To provide services at the highest level, we use cookies. Using the website requires you to choose settings related to their storage on your device. If you want to know what each type of cookie is used for, click the Details button below.

What is polyurethane foam and why is it used in mattresses? 2 grudnia 2021 |

Polyurethane foam, also known as PUR foam, is used across many industries. Polyurethane sponges are found in mattresses, furniture, medical products, and sports accessories. This is due to its versatile physical and chemical properties, which can be easily customized. Its resistance to mold and mildew and low thermal conductivity make it durable, comfortable, and usually hypoallergenic.

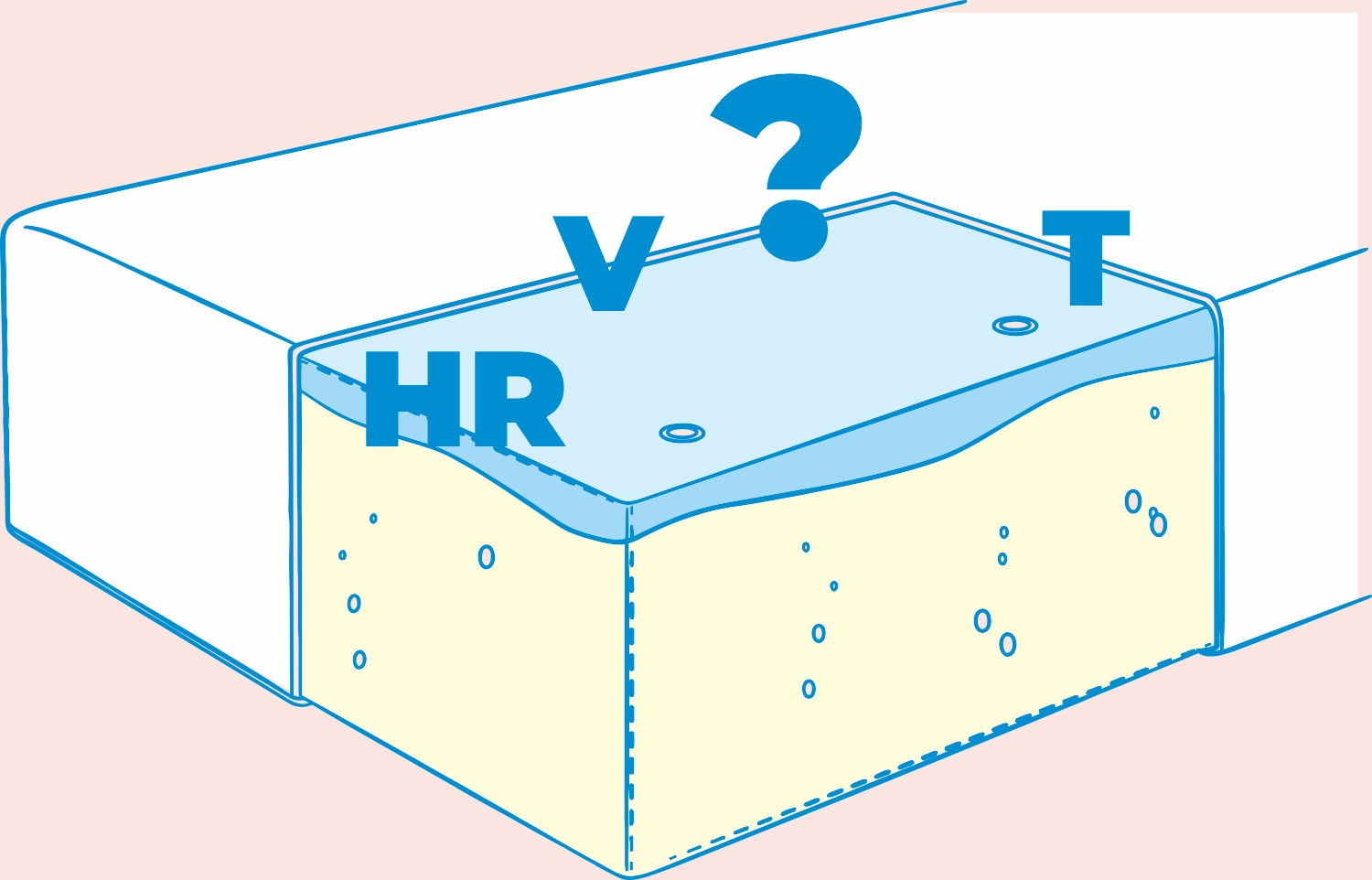

Yes, a polyurethane foam mattress can be excellent ? provided the foam type is appropriate. HR and V foams offer ergonomic comfort and durability due to their structure and performance. In contrast, cheap T foams quickly lose their qualities. Key factors include foam density, firmness, and a thoughtful, health-oriented design. It?s best to avoid T foams and also avoid mattresses with V foam as the top layer.

Absolutely, as long as it?s the right kind. HR foams (high resilience) are breathable, springy, and durable ? ideal for a hygienic sleep. V foams (memory foam) adapt to the body and reduce pressure points but limit airflow and have low responsiveness. That?s why they work best as a second layer. T foams are the worst option for sleep ? they are not durable and have a closed-cell structure.

The best mattresses combine HR foam in the top layer ? for breathability and stability ? with V foam underneath to contour the body. T foams are not suitable due to quick wear and poor ventilation.

PUR foams (especially HR and V) provide better body contouring, quietness, and hygiene than spring mattresses. Spring mattresses often use T foam as the comfort layer, which wears out quickly and reduces comfort. Polyurethane foam distributes body weight in all directions, while springs only move vertically. As a result, foam mattresses support the spine better ? regardless of whether the springs are classic, pocket, or multipocket, since the spring pockets are usually glued on the sides and top/bottom anyway.