To provide services at the highest level, we use cookies. Using the website requires you to choose settings related to their storage on your device. If you want to know what each type of cookie is used for, click the Details button below.

Visco foam - what risks does it pose? 1 kwietnia 2023 |

|

Visco foam is an extremely popular product used in the production of mattresses and pillows. When combined with high-density foam, it has led to a revolution in sleep hygiene. However, despite its many benefits, it is often used in a way that contradicts these values. Most mattress manufacturers use it improperly.

Despite all its advantages, visco foam can also have negative effects on our health and the environment. Therefore, when considering purchasing a memory foam mattress, it is important to understand the potential risks associated with it.

Currently, visco foam, also known as memory foam, is one of the most commonly used types of polyurethane foams, yet most consumers know very little about it. This phenomenon is caused by the fact that during the mattress buying process, we are often presented with false information that we are encouraged to believe by the salesperson.

All of this has made visco foam very popular worldwide, and the number of products that use this material continues to grow. As does the number of myths about it. Therefore, it is important to understand both the benefits it brings and the risks associated with its use.

Visco foam was invented by NASA in the 1960s when they were looking for a way to improve the safety of astronauts during rocket launches. The goal was to create a material that would provide cushioning and reduce pressure on the astronauts' bodies during launches and landings.

In practice, visco foam proved to be a very useful material for astronauts, but it quickly began to be used in other areas of life as well. Primarily in medicine, but also in the furniture and footwear industries. Thanks to some of its properties, such as flexibility, resistance to deformation, as well as the ability to absorb shocks and vibrations, visco foam has become a popular material for the production of memory foam mattresses and most orthopedic pillows.

The process of producing visco foam is quite complicated. The first step is to mix polyurethane with other ingredients, such as catalysts, fillers, and dyes. It can be produced by both chemical and pneumatic methods. Due to the costs associated with visco foam production, producers most often use the chemical method.

The chemical method involves combining isocyanates and polyols with alcohols, acids, and other substances. In the past, this was done by manually mixing the visco foam ingredients and then pouring them into molds to harden. Currently, the production process takes place on belts, onto which ready-made mixtures are poured from special nozzles whose composition is selected by computer. This method is more popular due to lower production costs. Moreover, it is usually carried out using TDI.

Production of visco foam by pneumatic method is based on creating foam by expansion using pressure and temperature, which allows for foaming of the polyurethane mixture. The mixture is injected into a mold, where under the influence of heat and pressure it begins to expand and foam. This method is more expensive, but allows for obtaining more uniform visco foam with a more even weight distribution. MDI is mainly used for injecting such visco foam into molds.

MDI and TDI are abbreviations for the chemical names of two different isocyanates used in the production of visco foam. The main difference between them is their reactivity. MDI, or methyl diphenyl diisocyanate, requires more time to react with polyols, but is characterized by high mechanical and thermal strength and good insulation properties. Meanwhile, TDI, or toluene diisocyanate, enters into faster reactions with polyols and is more resistant to wear, but has lower mechanical strength compared to visco foam made with MDI.

Visco foam produced by chemical method is characterized by very fast air release due to its internal structure. Meanwhile, the cells of foam produced by pneumatic method have porous membranes, which release air more slowly while maintaining better dynamics.

However, it should be noted that visco foam has many disadvantages that can only be mitigated by placing it in the second layer of the mattress. Also, in the case of pillows, it should be taken into account that orthopedic pillows cut from its blocks do not match the quality and ergonomics of those cast from molds. This applies to both visco foam and high resilience foam, which is used in ONSEN®.

Despite many benefits of using visco foam, it should be remembered that this material is not universal and has many drawbacks, especially when it is used in the production of sleeping mattresses, memory pillows, and other sleep-related products.

Visco foam belongs to viscoelastic foams, which result from the effects occurring in its internal structures. Being viscoelastic means being both sticky and elastic at the same time. However, in reality, there are no substances that are sticky and fully elastic at the same time. This means that visco foam loses elasticity with increasing viscosity.

To illustrate this on a scale, we could place peanut butter with high viscosity on the left end, followed by wood glue with lower viscosity, and then liquid soap, for example. At the far right end of the scale would be water, whose viscosity is close to zero. Meanwhile, visco foam is even stickier than peanut butter, but due to its elasticity, it is completely off the scale. Although it deforms under force, it returns to its original shape after the force is removed, which sets it apart from the rest.

In addition, visco foam is characterized by several effects that indicate its properties. First and foremost is the memory effect, which allows the visco foam to restore its structure after deformation, generated by the pressure associated with pushing the deformed material outward to restore its original structure.

However, three effects slow down the memory effect, namely:

These effects are closely related to the creep of the polymer in the visco foam, which causes it to stretch and deform even under a constant force. This effect is also dependent on the force applied, as slow application of force results in greater stretching than quick application. This also affects the relaxation effect, as less force is required to maintain the same level of stretching after deformation.

Importantly, visco foam differs significantly from other types of polyurethane foam in hysteresis testing, which measures the delay in response to pressure. It has been found that high-resilience foam takes about 6 seconds on average to fully relax and deform, whereas visco foam takes about 60 seconds. It also requires more energy to deform, which it does not fully return after relaxation.

Visco foam, also known as memory foam or memory foam, is a type of polyurethane foam that has the ability to conform to the shape of the body in response to heat and pressure. It is commonly used in mattresses, pillows, and other bedding items for sleeping. When used correctly, it can provide comfortable sleep and support for the body.

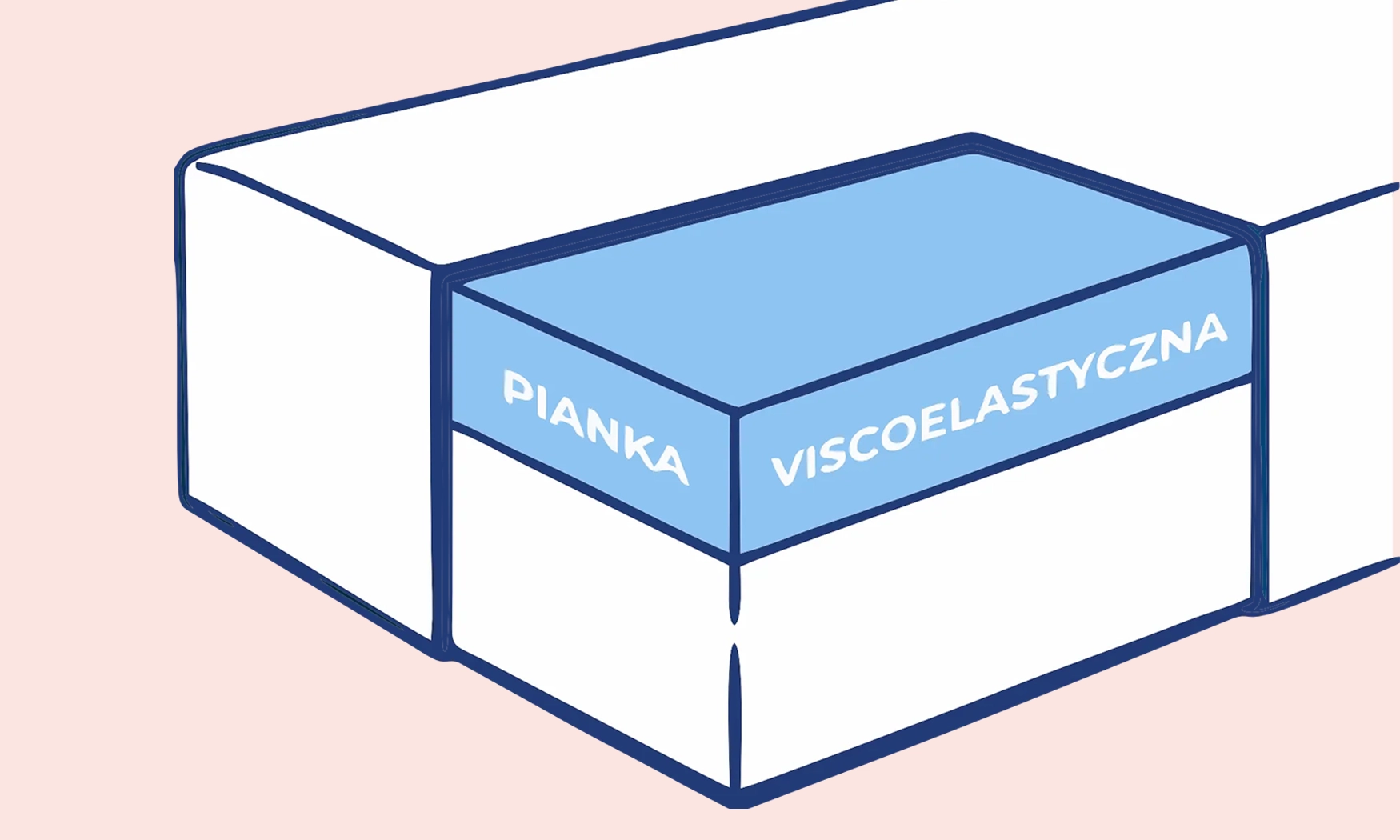

Visco foam reacts to the heat and pressure generated by the body of the sleeping person, conforming to their shape and enveloping it. At the same time, it has viscoelastic properties, which cause it to sink and significantly reduce air circulation. This allows visco foam to provide individualized fit and even pressure distribution, which can contribute to reducing pressure points and ensuring comfortable sleep, but only when placed in the second layer of the mattress.

Visco foam placed in the second layer of a well-designed mattress can offer many benefits, such as: individualized fit; reduction of pressure points; better pressure distribution; motion absorption; durability and longevity.

Visco foam is one of the most popular types of polyurethane foam. Placing visco foam in the second layer, between layers of high-resilience foam, and ensuring appropriate density and firmness, creates a versatile solution. Such a mattress, such as the Osaka Air mattress, is suitable for almost anyone.

Latex mattresses are not recommended due to the fact that latex does not have breathable and moisture-wicking properties. Additionally, latex can cause allergies in many people, regardless of its origin. Therefore, foam mattresses, including those made of a combination of high-resilience foams and visco foam, are a better choice. It is important in such a mattress that visco foam is not in the top layer. Additionally, attention should be paid to the type, appropriate density, and firmness of the polyurethane foams used in the mattress.