To provide services at the highest level, we use cookies. Using the website requires you to choose settings related to their storage on your device. If you want to know what each type of cookie is used for, click the Details button below.

Discover the secrets of design thinking in the world of sleep!26 marca 2022 |

Thanks to the ideas and plans generated in the previous stage of design thinking, we embarked on bold prototyping of our products. In each case, we took into account how the materials behave. Utilizing the entire knowledge of our team, we unanimously decided not to use viscoelastic foam, also known as memory foam, in ONSEN® orthopedic pillows. Both the knowledge gained in the design thinking process and from previous experiences excluded it from prototyping.

The use of viscoelastic foam in orthopedic pillows would not be beneficial for our potential customers, as it is very sensitive to temperature and weight. Therefore, it collapses during sleep, causing a lack of proper support for the head and cervical spine. Therefore, it is not suitable for people with reduced cervical lordosis or discopathy.

Although it is popular due to the large investments made by companies in marketing and advertising, most customers quickly give up on orthopedic pillows made from it. The exception is viscoelastic foam produced using pneumatic technology, which is used by another Polish producer - Dr Sapporo. It has different properties, which is why it is an exception. However, most, if not all, other companies use this type of foam produced using chemical technology, as it is several times cheaper.

We made a similar decision regarding our offered high resilience foam mattress, whose layered construction was fully thought out. In this case, viscoelastic foam is used, but only as its second layer. The first layer is made of open-cell high resilience foam of the HR type produced according to our proprietary recipe.

It was natural that we did not use coconut, buckwheat, springs, or closed-cell traditional T-type polyurethane foam in it. The properties of these materials make them unsuitable for creating functional sleep products. This was additionally confirmed by the experiences of people who participated in the entire design thinking process.

The arrangement of the individual layers of the Osaka Air mattress is designed to ensure maximum functionality. They are comfortable, hypoallergenic, and have European origin. Our goal in the design thinking process was to eliminate weight accumulation points to provide ideal body and spine support.

Additionally, we selected its hardness, flexibility, and elasticity to meet the needs of at least 93% of people. The result of design thinking was the development and creation of a unique ventilation system that reduces overheating of the body during sleep.

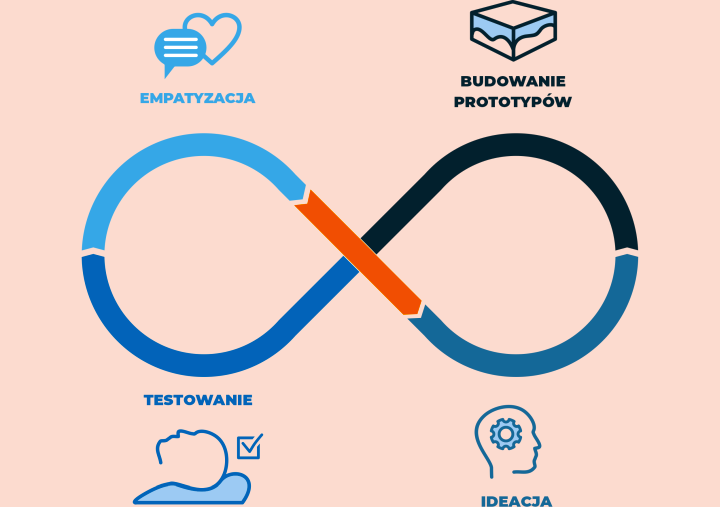

Design thinking to metoda projektowania skoncentrowana na użytkownikach. Stąd też design thinking opiera się na empatii związanej z problemami, które użytkownicy zgłaszają. Dodatkowo design thinking bierze pod uwagę różnice wynikające z demografii i psychografii, co pozwala na trafne zdefiniowanie ich potrzeb.

Myślenie projektowe to design thinking. Jest ono procesem zespołowym, który ma miejsce w ramach danej organizacji. Design thinking służy stworzeniu innowacyjnych rozwiązań, które mają na celu zrozumienie problemów i potrzeb użytkowników. Efektem myślenia projektowego, a więc design thinking, powinno być wdrożenie gotowego produktu, jaki na nie odpowie.

Design thinking to ludzka metoda, ponieważ opiera się przede wszystkim na empatii wobec użytkowników. Dobrze wykorzystany design thinking jest więc nie tylko ludzką metodą, ale i procesem, który rozpoczyna się od poznania realnych potrzeb użytkowników i szczerej chęci ich zaspokojenia.

Design thinking służy do projektowania i wdrażania rozwiązań, które mają za zadanie przynieść konkretny efekt. Dzięki design thinking poznaje się myśli i uczucia użytkowników, które pozwalają na wypracowanie ich profilu. Zadaniem design thinking jest rozwiązanie problemów użytkowników, a także odpowiedź na ich potrzeby.

Co do zasady design thinking składa się z 5 etapów, jakimi są: empatyzacja, definicja, ideacja, prototypowanie i testowanie. Dobrze przeprowadzony proces design thinking prowadzi do 6 etapu, którym jest wdrożenie wypracowanych rozwiązań i wprowadzenie produktu na rynek.